Vision Defect Detection Systems

Vision Defect Detection Systems

Quality control has been a major component of manufacturing since the assembly-line system was introduced by Henry Ford. The main idea behind forming an assembly line was that quality could still be achieved if everyone on the assembly line did their part. We've come a long way since then by replacing manual processes with machinery. However, quality control is still a big and costly issue today.

The main problem is that even if there is a slight defect in the materials that are not visible to the human eye, it can make the whole production run defective. We know that the defective product will not reach the end customer. However, relying on manual defect inspection means that a great number of items will be produced until the defect is detected. As a result, it will be costly to the companies.

Learn more about Defect Defection in Computer Vision from here.

Why do we need to move from manual to automated vision defect detection systems?

Firstly, as mentioned above, having a manual system is very costly for companies. Until the defect is detected in an inspection, probably thousands of items are produced at a significant expense. Secondly, companies need to put significant time and effort into training human experts to perform the inspections. Moreover, these inspections can slow down or, even worse, stop the production line. Lastly, most of the time, inspectors cannot reach the pace of production. The companies need further training to keep up with performing timely inspections.

Luckily, automated vision defect detection systems emerged as a replacement for manual systems. The benefits of this system include;

- Gathering information and statistics for improving manufacturing lines

- Enabling early error detection in the manufacturing process

- Reducing the number of waste and repair costs as a result of early error detection

- Also, reducing the number of added labor time and expenses.

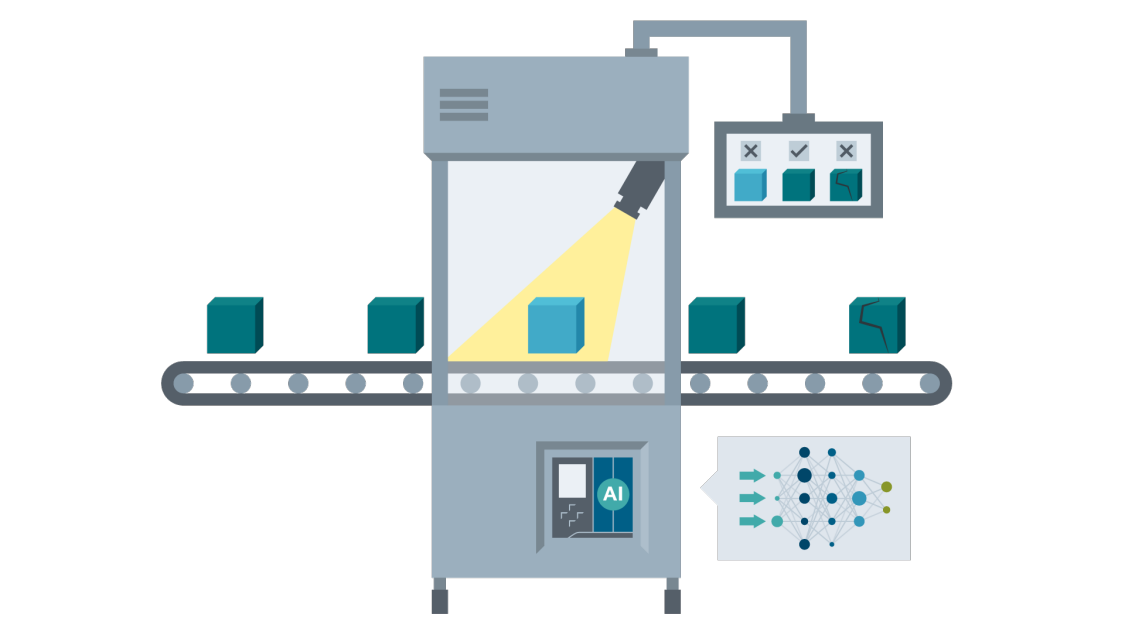

Automated vision defect detection systems are a major breakthrough in quality control. Deep learning and AI in vision defect detection systems aim to learn different types of defects in production lines and to conduct predictive analyses together with detecting defects. By integrating deep learning and AI, companies can eventually target error-free production.

How do we use AI and deep learning in vision defect detection systems?

In order to answer this question, first, we need to understand the concept of computer vision. It is a subdivision of machine learning and AI that allows computers to understand the content of images. In other words, it aims to do what human vision does. The mechanism behind deep learning is that machines learn by gathering more examples. Providing different examples enables computer vision to identify and classify objects by forming common patterns.

Deep learning-based vision defect detection is especially effective when detecting defects in complex surfaces or cosmetic defects such as scratches and dents. Moreover, these systems are capable of inspecting items more precisely and classifying them accordingly.

The vision defect detection systems are also easier to adapt when detecting defects that are not easily visible to the human eye or when the defects are hard to capture. The vision defect detection systems can easily complement already existing technology. This system allows for the computerization of visual inspections that are previously done by human expertise. With the help of vision defect detection systems, the limits of what computers, cameras, and sensors can accurately detect are broadened.

And now, Cameralyze is offering to use a defect detection system without buying any hardware. You can use your own cameras and start to detect defects in less than one hour. No need for any coding expertise. Let's start to use. Register for free and create your own workflow.